I'd like to bolt a hitch receiver onto my loader bucket, to make moving my gooseneck livestock trailer around a little easier. I installed a set of Taskmaster plates for my loader from JU Fabworks last year and I was very impressed with their quality. Unfortunately, they don’t offer a stand-alone hitch receiver. Can anyone recommend a good quality bolt-on? Thanks.

Loader Bucket Hitch Receiver

3P Ranch

Discussion starter

170 posts

·

Joined 2021

- Add to quote Only show this user

I'd like to bolt a hitch receiver onto my loader bucket, to make moving my gooseneck livestock trailer around a little easier. I installed a set of Taskmaster plates for my loader from JU Fabworks last year and I was very impressed with their quality. Unfortunately, they don’t offer a stand-alone hitch receiver. Can anyone recommend a good quality bolt-on? Thanks.

20,239 posts

·

Joined 2012

This is the one BoltOnHooks sells. You can add a backing plate for improved strength on the bucket edge. It also makes a nice clevis anchor.

www.boltonhooks.com

www.boltonhooks.com

![Image]()

![Image]()

Bolt-On Hooks - BoltOnHooks LLC

Bolt-On Hooks and other accessories for compact tractors. BoltOnHooks LLC / KBOH-USA

663 posts

·

Joined 2020

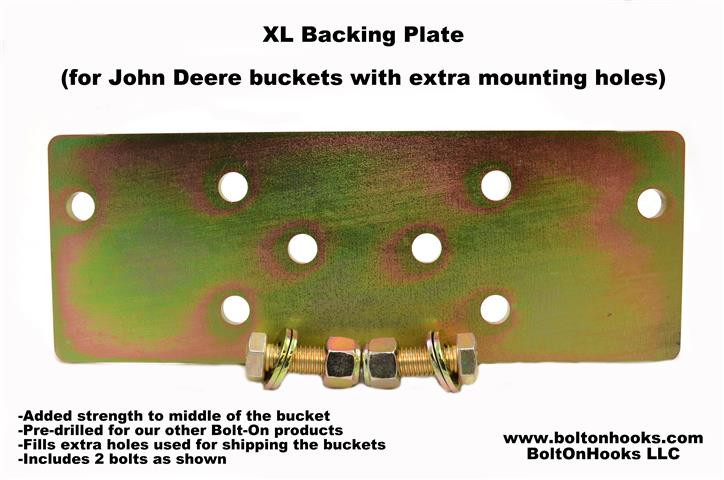

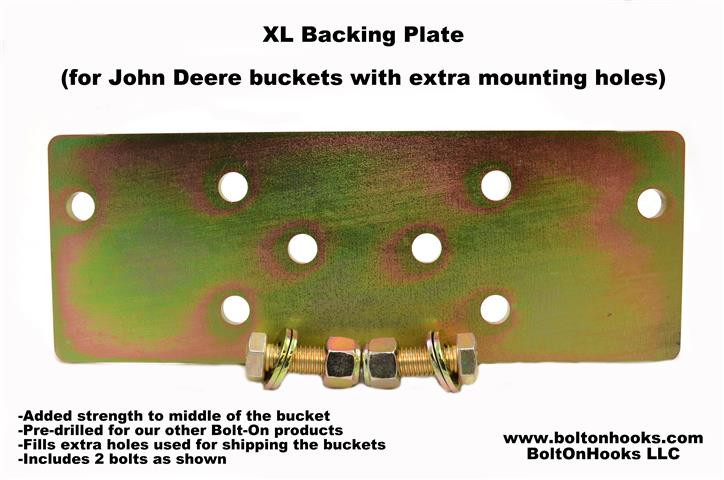

Here is something else you might want to consider adding to the one jgayman recommended if you want a little extra support.

![Image]()

www.boltonhooks.com

www.boltonhooks.com

XL Backing Plate - BoltOnHooks LLC

For JD buckets with the two extra mounting holes on top. Drilled for our Bolt-On Products Made in the USA Video posted on our YouTube Channel! *Includes two bolt sets*

1,459 posts

·

Joined 2014

Hey, I just bought that and matching bolt on receiver for the HD bucket on my 220R MSL. Haven't got it on yet though.😊

Allen.

Allen.

17,636 posts

·

Joined 2014

Just be careful as the center of the bucket is the weakest point of the bucket and it doesn't take much to twist it out of shape. Ken's hitch is plenty strong, its the bucket which will bend and twist with much weight put on it..............How much is too much? As far as I know, its not been "officially tested"........

I mounted the 2" receiver tube under the rear area of the tractor where there should be a draw bar. Heavy Hitch sells a rear mounted hitch which will bolt right on the plates on the back of the 1 series, and it doesn't interfere with PTO connection.

If you do use a Heavy Hitch receiver on the back of the tractor, you will have to invert the ball mount and mount the ball on the high side, to get the trailer tongue level. You may need quite a drop ball mount inverted to pull the trailer level. I have one trailer where I use a 11" drop ball mount, flipped upside down, to secure to the trailer hitch.....Also note, you can put the 3ph carry all on the tractor with the hitch and ball mount left in place. I also use a hitch extension, as shown as you can not mount the ball mount into the rear receiver as the front of the trailer will hit the rear tires on the tractor,. I think my hitch extension is either 12" or 15" long.............

![Image]()

![Image]()

heavyhitch.com

heavyhitch.com

I mounted the 2" receiver tube under the rear area of the tractor where there should be a draw bar. Heavy Hitch sells a rear mounted hitch which will bolt right on the plates on the back of the 1 series, and it doesn't interfere with PTO connection.

If you do use a Heavy Hitch receiver on the back of the tractor, you will have to invert the ball mount and mount the ball on the high side, to get the trailer tongue level. You may need quite a drop ball mount inverted to pull the trailer level. I have one trailer where I use a 11" drop ball mount, flipped upside down, to secure to the trailer hitch.....Also note, you can put the 3ph carry all on the tractor with the hitch and ball mount left in place. I also use a hitch extension, as shown as you can not mount the ball mount into the rear receiver as the front of the trailer will hit the rear tires on the tractor,. I think my hitch extension is either 12" or 15" long.............

Rear Receiver Hitch Plate for John Deere 1000 Series Tractors | Heavy Hitch - Compact Tractor Attachments

Upgrade your John Deere 1000 Series tractor with a 2 inch Rear Receiver Hitch Plate. Perfect for towing and attachments, durable, and made in the USA.

3P Ranch

Discussion starter

170 posts

·

Joined 2021

Thanks for the photos, as I posted however, I‘m in need of a loader mounted hitch receiver to move my gooseneck livestock trailer. I have the below attachment that allows me to tow gooseneck or bumper pull trailers with my 3 point, but I’ve found it hard to maneuver my gooseneck, when trying to BACK it into it’s tight parking spot. I‘m thinking it would be easier to park it with it attached to the loader. As you pointed out, weight of course is a concern, so I will need to be cautious. I will only be moving it while it’s unloaded.I mounted the 2" receiver tube under the rear area of the tractor where there should be a draw bar. Heavy Hitch sells a rear mounted hitch which will bolt right on the plates on the back of the 1 series, and it doesnIf you do use a Heavy Hitch receiver on the back of the tractor, you will have to invert the ball mount and mount the ball on the high side, to get the trailer tongue level. You may need quite a drop ball mount inverted to pull the trailer level. I have one trailer where I use a 11" drop ball mount, flipped upside down, to secure to the trailer hitch.....Also note, you can put the 3ph carry all on the tractor with the hitch and ball mount left in place. I also use a hitch extension, as shown as you can not mount the ball mount into the rear receiver as the front of the trailer will hit the rear tires on the tractor,. I think my hitch extension is either 12" or 15" long.............

Wondering at this point whether I should use a straight or drop ball mount…?

Thanks everyone for the help. I’ll be giving Bolt On Hooks a call.

17,636 posts

·

Joined 2014

The weight of the Gooseneck Livestock trailer on the bucket top edge would be a major concern. While its not just the tongue weight of the gooseneck hitch, its the weight of the empty trailer you are going to be pushing with the top edge of the bucket. It would probably be a very good idea to build some type of reinforcement to hold the top edge of the bucket in place because the hitch is going to want to roll the top bucket edge either up or down because of the trailer weight. I know the goal is to be able to see what you are doing more easily by having the trailer out front. Just be careful not to twist that top edge of the bucket. Its much easier than people think.........

The other option would be to mount a 2" receiver tube on the bottom front lip of the bucket, which does have the strength to handle the trailer weight. Then you could raise the bucket to get the trailer gooseneck to hitch to the sleeve on the front of the bucket.

If you have pallet forks, you would also be able to either put a gooseneck ball on one of the forks and slide the forks into the center of the frame. Or even mount the receiver tube to the frame itself, removing the forks. Of the different choices out there, the top of the bucket is the one which has the least strength based upon the way the bucket it made.

The top of the bucket is more to tie the sides together than it is a "working edge". The metal on the top of the bucket isn't designed to structurally "do work" it's more to complete the bucket shape........It's also why Ken's hooks are usually installed directly over the attachment point with the loader arms as that area is much stronger than the center of the top of the bucket..........

Personally, if I had to have the hitch out front, I would probably use something like this and then flip a ball mount to get the hitch ball as high as possible to give you both bucket clearance on the surface, and visibility to see while backing the trailer.......

The other option would be to mount a 2" receiver tube on the bottom front lip of the bucket, which does have the strength to handle the trailer weight. Then you could raise the bucket to get the trailer gooseneck to hitch to the sleeve on the front of the bucket.

If you have pallet forks, you would also be able to either put a gooseneck ball on one of the forks and slide the forks into the center of the frame. Or even mount the receiver tube to the frame itself, removing the forks. Of the different choices out there, the top of the bucket is the one which has the least strength based upon the way the bucket it made.

The top of the bucket is more to tie the sides together than it is a "working edge". The metal on the top of the bucket isn't designed to structurally "do work" it's more to complete the bucket shape........It's also why Ken's hooks are usually installed directly over the attachment point with the loader arms as that area is much stronger than the center of the top of the bucket..........

Personally, if I had to have the hitch out front, I would probably use something like this and then flip a ball mount to get the hitch ball as high as possible to give you both bucket clearance on the surface, and visibility to see while backing the trailer.......

Clamp On Trailer Hitch 2" Ball Mount Receiver Bucket Bobcat Trailer Tractor Tow | eBay

Clamp On Bucket W/ 2" Ball Hitch. 2pcs Clamp on Bucket W/ 2" Detachable Ball. 1 x Clamp On Trailer Receiver Hitch. Do you need to refit your tractor loader or skid steer to be a trailer?. It can works with all of 2" hitch inserts,you just need to Tighten the screws to fix it on the bucket.

www.ebay.com

3P Ranch

Discussion starter

170 posts

·

Joined 2021

SulleyBear, thanks so much for your insight, I really appreciated it. You have me re-thinking this idea. The suggestion about using a pallet fork may be the way to go. My local gooseneck trailer manufacturer moves their trailers around their assembly plant with a forklift, using a single pallet fork, as you suggested. They drilled a hole in the pallet fork and mounted a ball.The weight of the Gooseneck Livestock trailer on the bucket top edge would be a major concern. While its not just the tongue weight of the gooseneck hitch, its the weight of the empty trailer you are going to be pushing with the top edge of the bucket. It would probably be a very good idea to build some type of reinforcement to hold the top edge of the bucket in place because the hitch is going to want to roll the top bucket edge either up or down because of the trailer weight. I know the goal is to be able to see what you are doing more easily by having the trailer out front. Just be careful not to twist that top edge of the bucket. Its much easier than people think.........

The other option would be to mount a 2" receiver tube on the bottom front lip of the bucket, which does have the strength to handle the trailer weight. Then you could raise the bucket to get the trailer gooseneck to hitch to the sleeve on the front of the bucket.

If you have pallet forks, you would also be able to either put a gooseneck ball on one of the forks and slide the forks into the center of the frame. Or even mount the receiver tube to the frame itself, removing the forks. Of the different choices out there, the top of the bucket is the one which has the least strength based upon the way the bucket it made.

The top of the bucket is more to tie the sides together than it is a "working edge". The metal on the top of the bucket isn't designed to structurally "do work" it's more to complete the bucket shape........It's also why Ken's hooks are usually installed directly over the attachment point with the loader arms as that area is much stronger than the center of the top of the bucket..........

Personally, if I had to have the hitch out front, I would probably use something like this and then flip a ball mount to get the hitch ball as high as possible to give you both bucket clearance on the surface, and visibility to see while backing the trailer.......

When I looked more closely at the eBay link you posted for the clamp-on ball mount, I spotted the below little beauty. This just be the way to go. What do you think?

12 posts

·

Joined 2021

How about this? But, but, but it's made by gasp Titan. <end sarcasm> I own three attachments from Titan and they all fit and do what I need them to do.

www.palletforks.com

www.palletforks.com

3 Point Attachment Adapter Fits John Deere

The Titan Style 3 point attachments plate fits John Deere & provides easy three-point attachment to category 1 implements.

3P Ranch

Discussion starter

170 posts

·

Joined 2021

I did gasp at the mention of Titan, LOL! I bought two attachments from them and regretted both purchases. Their CS is the worst. This does give me another alternative though, thanks.How about this? But, but, but it's made by gasp Titan. <end sarcasm> I own three attachments from Titan and they all fit and do what I need them to do.

418 posts

·

Joined 2019

Please do not think you can drill through pallet forks. Unless you all know something I don't, which I know you do. I spent a couple of hours trying to drill a hole in my pallet fork so I could put a ball in the hole. I even went to a neighbors house and dulled a few of his bits on his press. Finally, I went to the farmer next door and asked him how he did it. He has holes in his pallet forks. He said, oh you can't drill them you have to burn them. 5 minutes later I was headed home with a nice torched hole in my pallet fork. It wasn't pretty, or round but it works.

3P Ranch

Discussion starter

170 posts

·

Joined 2021

Oh no…I definitely know LESS than most on here, LOL!

I kinda knew that about the pallet forks though. My son is a certified forklift tech, he’s passed some of his tips on to me. We both have a concern though that putting the weight of the gooseneck that far out from the loader pin might be a bad idea, so I am looking at other options.

Thanks!

I kinda knew that about the pallet forks though. My son is a certified forklift tech, he’s passed some of his tips on to me. We both have a concern though that putting the weight of the gooseneck that far out from the loader pin might be a bad idea, so I am looking at other options.

Thanks!

2,254 posts

·

Joined 2018

Could just drill a hole in your bucket at whatever size the shank is, and bolt a 2-5/16" ball in it. Use a piece of steel on the bottom side as a a backer to help distribute the load.

K.I.S.S.

K.I.S.S.

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 1.7M

- members

- 91K

- Since

- 2010

A forum community dedicated to John Deere tractor owners and enthusiasts. Come join the discussion about towing, PTO’s, reviews, attachments, modifications, troubleshooting, maintenance, and more!

Our Vendors

View AllTop Contributors this Month

View All

flyweight

236 Replies

MarkEagleUSA

201 Replies

Kbar

147 Replies