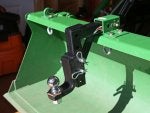

When I had my trailer sales lot, we fabricated a rectangular piece of box steel tubing that was close to the same width as the non tapered part of the pallet forks and about as thick as the pallet forks. We drilled a hole into the center top of the mount where the hitch ball would be mounted to the top of it. We welded the hitch ball nut on top of the mount.

When we would slide the tubing over the taper in the end of the fork, when it was snug on the fork, about 12" in from the fork tip, we would take the hitch ball size we needed and thread it into the nut on top. Then we would use either a open ended wrench which fit the flange on the hitch ball or a large pipe wrench and tightened the ball down onto the fork.

There was a smaller nut on each side of the bracket with 5/8" or 3/4" bolt which could be tightened on the sides of the mount to hold it as well. The thought was since we would be changing between 2" and 2 5/16" ball sizes, the side bolts would secure the mount in place when swapping the hitch balls.

Then we just made a second bracket and left the 2" ball on one bracket on one fork and the 2 5/16" ball on the other bracket on the other fork. Very easy to put on and take off and it never moved once on the fork. Worked quite well...............

I insisted we try this as one guy at the shop wanted to drill a hole through the end of the fork to allow the hitch ball to be mounted. We didn't drill the pallet fork after this worked out just fine.

Pallet forks are handy to move and position trailers as the visibility is great and the forks stick out and allow you to position the trailer in the space without having to drive the tractor in the work bay, etc. Also, with the forks being skinny, you can 90 degree turn the trailer tongue and not jackknife the tongue into the tractor bucket, etc.and damage anything.

Plus you can lift it off the tongue jack and set it back down without ever having to get off the tractor. I would position blocks of wood to set under the tongue jack posts so they didn't score the asphalt when setting them down.

Someone with software skills could likely draw the item I am describing for all to see. It's very simple. However, I am not that person with the drawing skills.....:laugh::lol: